Your partner in Weighing Solutions, Material Handling & Lifting Equipment

Batch Processing

Specification

In current age, manufacturing units are becoming more complex, larger and tightly integrated. Customers are looking for manufacturing process details more transparently and in real-time. Engineering, maintenance, and productions departments are required to optimize production efficiency, improvise quality while reducing cost.

Batch processing is the process in which series of operations are carried out on a material or combination of materials over a period of time. Batch processing is at the heart of core operations of most of the chemical, Agrochem, pharmaceutical, paint & pigment industry Endel Digital’s LABMAST is a refreshingly new Digital platform for helping customer optimize their batch management processes. LABMAST is designed with ease of operations and User personas in mind so that users at each level benefit through this digital transformation

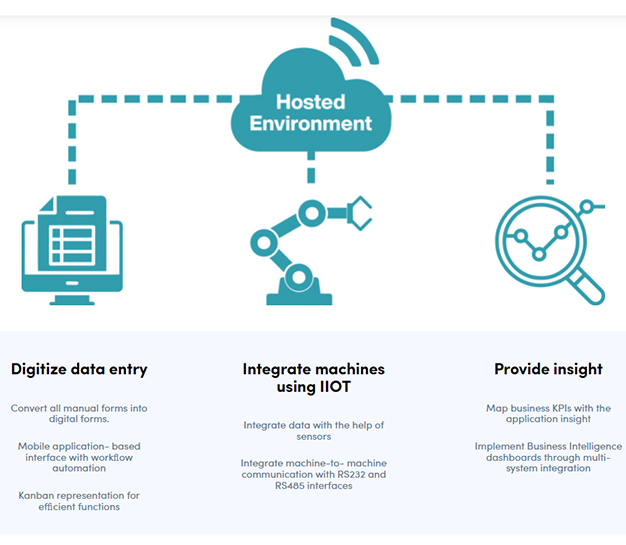

Endel Digital’s LABMAST Is Industry 4.0 Solutions And Is Based On The Tenets Of;

Checklist

- Auto-assignment of checklist to the person on shift .

- Checklist is devised in a sequential manner

- Time bound control and automatic notifications to the direct supervisor

- Provides comparison reports with previous shifts and completed checklists.

- Option to read QR Codes or NFC Tags attached to the asset for the identification of the asset

- Web dashboard shows upcoming checklists, pending checklists, failed checklists

- Alert controls for repeated checklist failures (Frequency can be configured in the master settings)

- Mandatory comment inputs for the failed tasks in the checklist

- Mandatory photo capturing for each critical activity on the checklist

- Auto-email notification with filled checklist

Material Issuances Note

- Create complete product master with current stock codes.

- Operator can select stock codes from the drop-down menus and specify each quantity

- Supervisor must approve the workflow, for the MIN to be made

- MIN must be approved, before the material is issue

- Packaging material quantity is automatically selected based on the quantity of the other materials in the MIN

- Suggestive EBQ based on formula provided

Suggestive EBQ Based On Formula Provided

- Retrieve complete MIN from the ERP Records.

- Select job numbers from ERP System directly

Worksheets

- Auto-generation of worksheet based on the MIN.

- Prepopulate material code based on the MIN with option for operator to add more material (initial load)

- Auto-populate the batch cycle time based on the readings and place it next to the theoretical batch time

- Automatically calculate standard loss and actual loss based on the pre-defined formula.

- Worksheets will be assigned by supervisor and will have handover option

- Pre-existing entries can only be edited by supervisor

- Auto-calculate the final yields based on the pre-defined formula

- Sample collection scheduling, auto-alerts for missing the scheduled times

- Mandatory final quality testing

- Integrate panel temperature, to automatically trigger alarm for threshold.

Product Transfer Note:

- Auto-generate product transfer note based on the worksheet output

- Dropdown menu for known field in the quality control parameter with expected result mapping

- Exception in quality control parameter should trigger email notification and should be visible in dashboard

- Option to export and mail the PTN in pre-defined format

- Option to edit the entries in the product transfer note by supervisor.