Your partner in Weighing Solutions, Material Handling & Lifting Equipment

Tank Weighing

Description

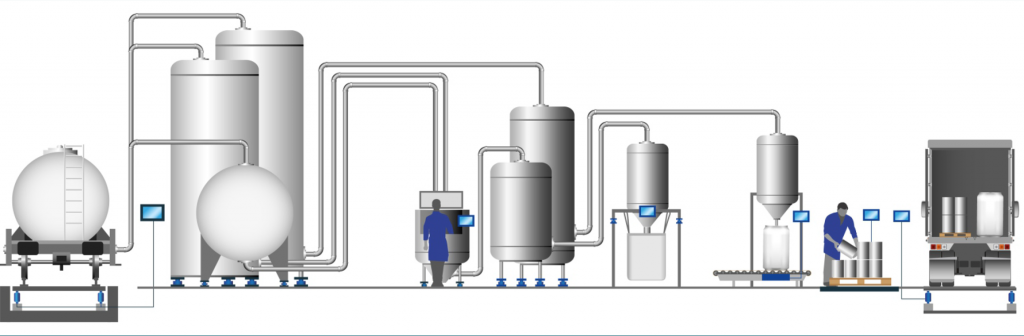

Any manufacturing process requires you to have reliable visibility and accurate count of all the raw materials across the manufacturing supply chain, without this there cannot be a smooth-run process. The weights and measures of the ingredients stored in large vessels, tanks, silos, and hoppers. The process of weighing and measuring the ingredients needs to be done in a quick and smooth manner, to avoid inefficiencies. Traditional tank weighing systems utilize hardware that provides only basic information. Endel Digital has created the revolutionary first-of-its-kind tank weighing software, that provides greater visibility and insight into the data.

Why does your manufacturing process need this?

Less waste

Less risk

Easier to connect

More insightful data

Less time for integration, configuration, and implementation

More productivity and scalability

What does our Tank weighing software give you?

Reports on utilization of materials

Key purpose of tank weighing is the inventory control methods for the measurement of high-value solids, liquids, and gases inside tanks, silos, and more. They can hold up to 1000 Tons worth of valuable material, making it even more important to receive accurate information regarding the utilization of these materials. Traditional systems rely on human efforts to organize and present data, leaving room for inefficiencies and malpractices. Endel Digital is here to help you solve that.

Our system allows for process data to be gathered from a variety of devices, including existing tank weighing systems, sensors, as well as manual data entries. Eliminating manual data tracking and reporting saves time and reduces chances of errors. RS232 and Ethernet TCP/IP connection interface provides smooth communication between the machines and the software.

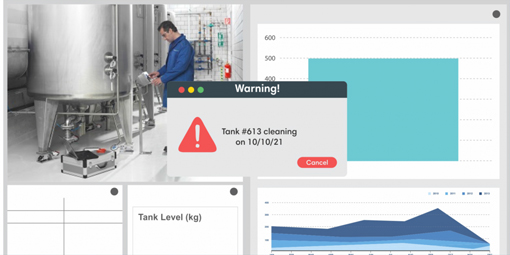

Alerts and reminders of maintenance and

tank cleaning schedules

Tanks, silos, and hoppers require timely maintenance and cleaning, to ensure the health and hygiene of the tanks and the manufacturing plant. The maintenance and cleaning of tanks requires a temporary shutdown of the processes, and if this is not scheduled appropriately can cause large scale and expensive disruptions. Our software integrates the maintenance and cleaning schedules of every tank in the manufacturing plant, regular reminders and alerts are there to ensure that the relevant personnel is aware about the shutdown and can rearrange the processes accordingly.

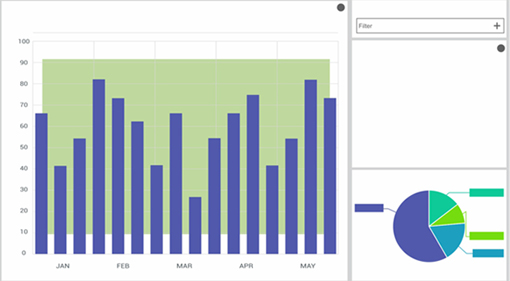

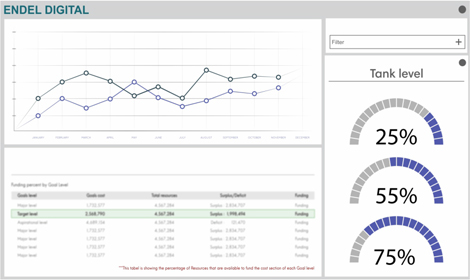

Single dashboard providing complete data visibility

Completely customizable easy-to-read dashboards that gives you real-time insights into your processes. Dynamic and engaging graphic visualization lets you easily analyze the current production statuses, and track key performance indicators. Every individual and every organizational role get access to data that is only relevant to them.The senior management can track production efficiencies and process performances for different workstations. This allows the team to make educated business decisions, and reallocate the resources in the most efficient manner.Cloud-based access allows remote access to data, through any computer or desktop.

Enhance processes through predictive maintenance

Do you want to know if your tank-weighing performance was deviating, before it starts to cost you money? Big data processing through cloud, allows for predictive algorithms to help figure potential errors. This helps provide improvements across all production areas, and helps identify gaps in the processes. Digitalization allows the key decisionmakers to access live process data at their fingertips.

Application

Industries

Agriculture

FMCG

Food manufacturing

Chemicals

Pharmaceuticals