Your partner in Weighing Solutions, Material Handling & Lifting Equipment

Weighing Solutions for Mining Industries

Description

What makes Endel’s Mining Solution ideal for you?

Process automation designed to align with mining operations

Endel’s ‘WeighMAST for Mining’ integrates seamlessly with the ERP system of the company, so that truck registration numbers can be cross-checked with reference data.

To ensure that the truck is positioned properly on weighbridge platform, the system deploys multiple high-reliability sensors and feedback is provided through Red/Green Color traffic signals. This traffic light system ensures that the truck does not leave the weighbridge, until the accurate weighment data has been captured.

Additionally, live camera feeds are provided via the operator console to quickly validate the truck and its position, resulting in faster throughput and improved operational efficiency

The weight data is automatically and securely saved to the ERP database where it can be used for invoicing or to help with inventory management. Photographs of each truck that passes over the weighbridge are also captured and stored for review and auditing purposes.

In the traditional weighbridge operations, it was left to the operators’ discretion to check the vehicle’s position on weighbridge platform and there was no way to enforce it or verify if it was done. With our software, the company no longer has to rely on the operator’s skill to get the correct weighing data, and storing it in the right manner.

Scalability through integration of various

Weighbridges across premises

Businesses that have very large premises across different locations, would be operating different Weighbridges. WeighMAST allows Weighbridges to be connected and integrated with one other seamlessly, ensuring that the information regarding vehicle movement and material movement is shared to the right people. WeighMAST allows for scaling up the weighbridge operations with extreme ease, allowing for up to 50 Weighment transactions taking place within one minute.

Integration with PO/SO/Vendor Management

WeighMAST for Mining' can be integrated for Vendor management, where different product category, set rate for the products, sizing parameter for each product can be set. All this data is fetched by SAP which is integrated with the system. Every weighment transaction can be associated with a PO/SO and a specific vendor or supplier, this provides very clear data visibility and avoids any miscommunication amongst the team members. The data is fetched from the cloud and allows the operator, or gate security to ensure whether the right product, with the right characteristics are being brought into the organization.

Integration with complete mining process; from harvesting to supplying.

Mining industry has a value chain with various interdependent steps. Starting from the extraction to shipping, WeighMAST allows you to accurately track the weight across all the various sites and locations.

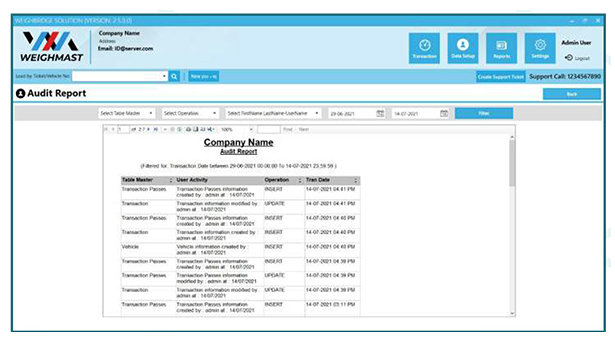

Complete Smart Reporting and Cloud-Based Data Management

Out of Box Reports

Supplier wise products

This report would record the number of times a particular supplier has provided the products to your business. With the help of SAP integration, and product management, every time an inwards weighment transaction is made, the source of the material is recorded. This allows WeighMAST to develop reports of how many times a particular supplier has provided goods to the business.

Vehicle wise reports

Businesses need to be aware of which vehicles are passing through its campus, which vehicles are moving inwards, and which are moving outwards. At the time of the weighment, the system records the number plate data and the data of the truck driver, which is used to generate this report. It allows the company to know which vehicles have come in on which dates, and how many times each vehicle has entered or exited the premises. This level of detail would prove extremely useful when theft or any form of malpractices are detected.

Product wise reports

This report will record the movement of a particular product or a specific product group, that had either entered or exited the campus during a fixed period. this report can be generated on a daily, weekly, fortnightly, or monthly basis.

Date range reporting

The report presents the number of weighment transactions done by the business between a fixed period.

Cloud Based Reports

Trend analysis of any variable such as truck, material, supplier, specific dates can be accessed from anywhere, using any device, as it is present on the cloud. Here we are highlighting one of our many different cloud-based reports.

Supplier wise products

This report would record the number of times a particular supplier has provided the products to your business. With the help of SAP integration, and product management, every time an inwards weighment transaction is made, the source of the material is recorded. This allows WeighMAST to develop reports of how many times a particular supplier has provided goods to the business.