Your partner in Weighing Solutions, Material Handling & Lifting Equipment

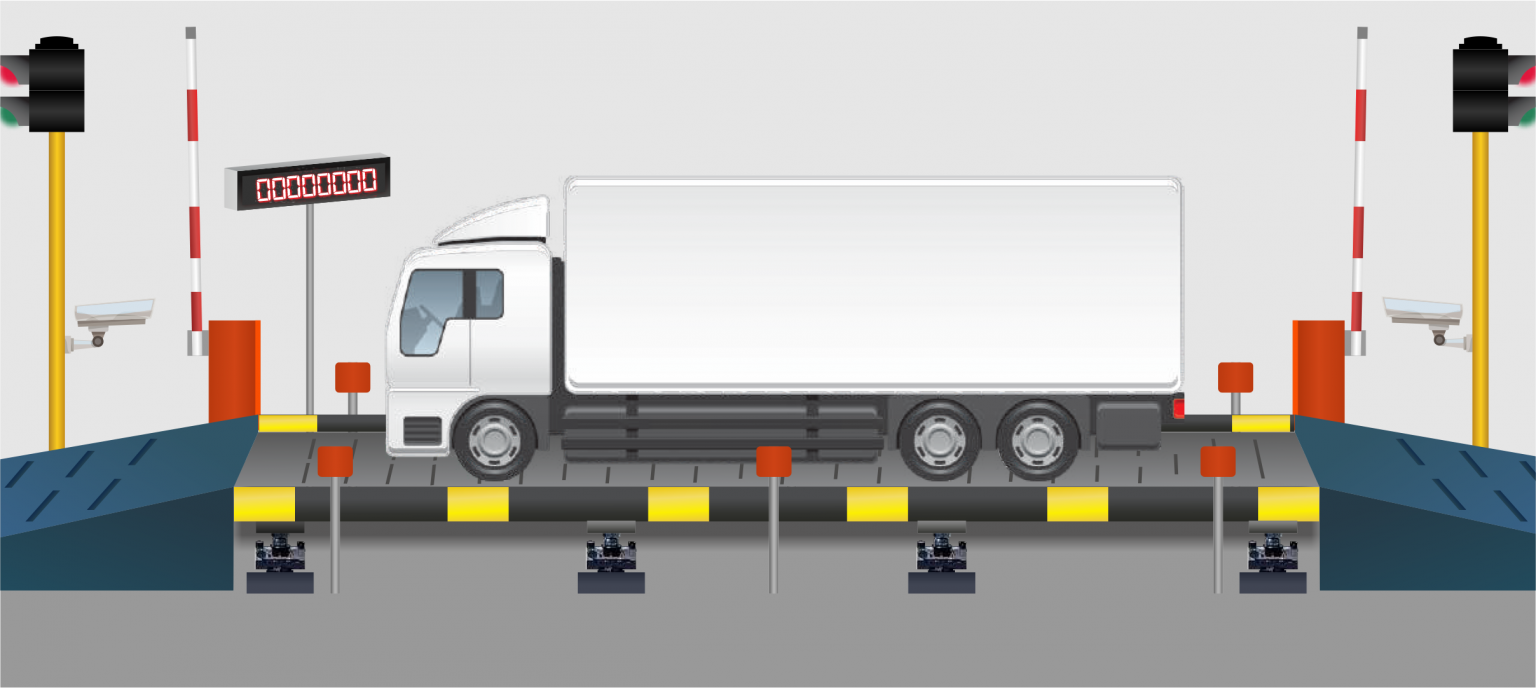

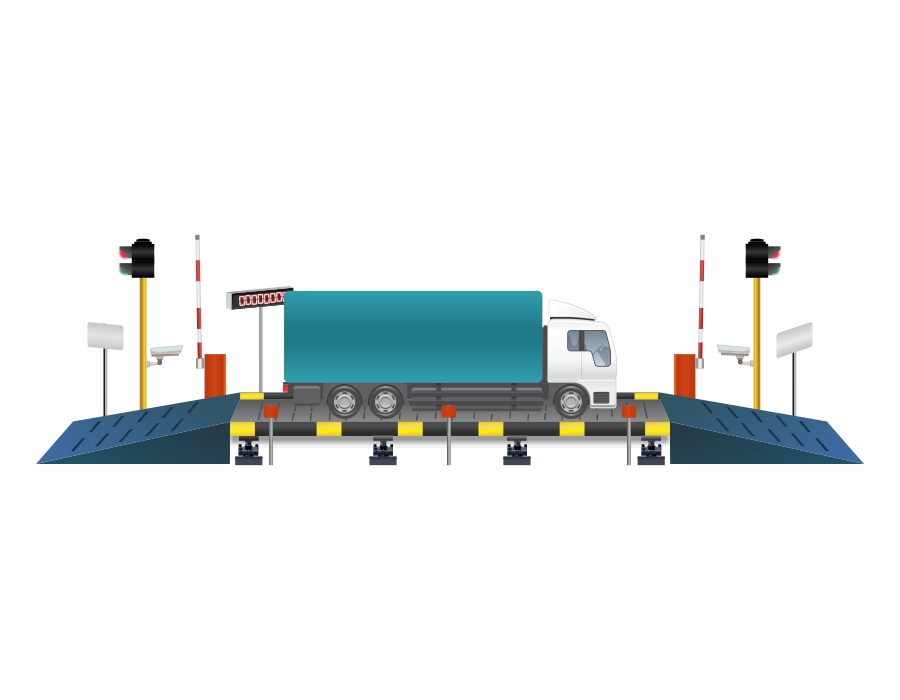

Unmanned Weighbridge System

Specification

What is Unmanned Weighing?

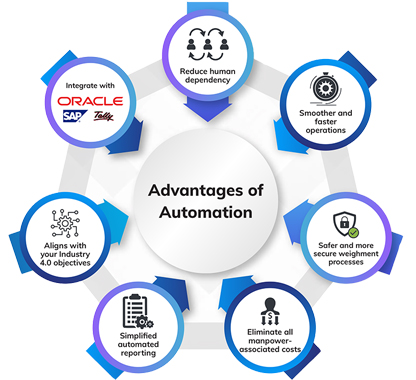

Weighing automation is the future of weighing operations. Industries across the globe require weighing to measure materials across all the phases of the supply chain, which makes human reliance and dependency very dangerous. Endel Digital Solutions is here to solve all the problems created by the traditional weighment systems.

Manpower costs

Sites that run 24/7 operations require multiple weighbridge operators, the wages of the operators and the supervisors are a significant cost to the organization

Delay in operations

Manpower-dependent operations always experience delays due to unforeseen circumstances.

Errors in data capturing

intentional or unintentional errors in the data capturing can cause significant discrepancies and issues moving ahead in the supply chain operations.

Difficulty in supervision and reporting

as all the data is manually captured, there are high chances of errors, which are difficult to fix at a later stage, and manually prepared reports are time consuming and inaccurate due to the inaccurate data

Why should you invest in upgrading your weighbridge?

How to prevent theft at your weighbridge?

From our years of experience and working with clients across numerous industries, We have gained a deep understanding of the problems that our clients have regularly faced, in terms of theft. Traditional weighbridge systems allow certain weighbridge malpractices to go unnoticed. One of the biggest malpractices that causes huge losses to any organization is theft. The amount of Weighment thefts occurring globally, have significantly risen over the years and this has become a major concern for all companies that utilize weighbridges at their facilities, big and small organizations are falling victim to these malpractices which result in huge losses

There are many other ways in which a weighbridge can be cheated, and theft may occur, we will be highlighting some of these ways and how WeighMAST solves these problems, and reduces the chance of theft.

Hardware Components

Control Panel

RFID Reader / ANPR Camera

Position sensors

IP Camera

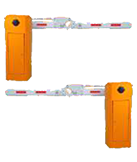

Barricades

Traffic lights

Jumbo display

Announcement system

Software Components

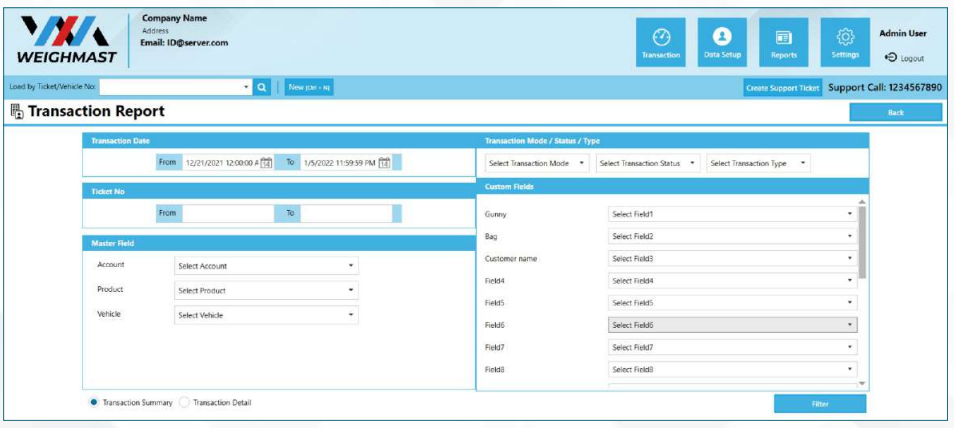

WeighMAST - Weighbridge data management software