Your partner in Weighing Solutions, Material Handling & Lifting Equipment

Various Types Of Checkweigher

Description

A checkweigher is an automatic or manual machine for checking whether the weight of a packaged commodity is within a specified range. It is normally found at the end of a production or packing line and is used to ensure net weight compliance.

Features:- Good accuracy at high speed

- Efficient rejection system with multi-weight zone

- Replacing labor for sorting, saving cost, improving efficiency & optimizing the production process.

- Complete control over production process thru customised reports and distribution chart

- Sea food industry,

- Aquatic & frozen products industry,

- Packaging industry,

- Flour mills,

- Chemical industry

- Pharmaceutical industry

- Poultry

Application

- Checking underweight / overweight products

- Identifying missing components in a package

- Feedback to the batching system

- Product sorting by weight

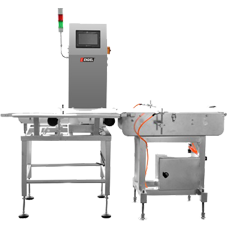

Standard Checkweigher

Introduction :Standard checkweighers are used mainly for packed products like bags, pouches, cans, bottles etc.

Checkweigher for heavy objects

Introduction :Checkweighers For Heavy Objects Are Used For Products Which Weigh In Excess Of 25kgs. The Throughput Is Normally Less.

Combi-Check (Checkweigher and Metal Detector)

Introduction :Combi checks are ideal where there is a requirement of check weighing and metal detection in the same line. Combichecks are highly recommended in production lines where there is a space constraint.

Sorting Checkweigher

Introduction :Sorting checkweighers are used where bulk products are required to be sorted by weight can be used for fish, fruit and vegetables.