Your partner in Weighing Solutions, Material Handling & Lifting Equipment

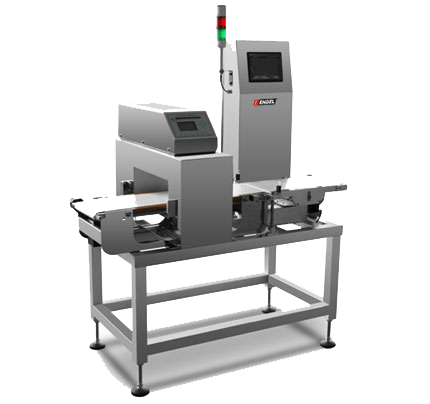

Checkweigher (Combi-Checkweigher and Metal Detector)

Description

Introduction :

Checkweigher is ideal where there is a requirement of check weighing and metal detection in the same line. Checkweigher are highly recommended in production lines where there is a space constraint.

A checkweigher is an automatic or manual machine for checking whether the weight of a packaged commodity is within a specified range. It is normally found at the end of a production or packing line and is used to ensure net weight compliance.

Features:- Replacing labour for sorting, saving cost, improving efficiency & optimizing the production process

- Complete control over process through customized reports and distribution chart.

- Sea Food Industry

- Aquatic & Frozen Products Industry

- Flour Mills

- Poultry

Specification

|

Model |

END-EMC-230L |

END-EMC-300 |

|||||||

|---|---|---|---|---|---|---|---|---|---|

|

Detecting Range |

20~2000g |

20~5000g |

|||||||

|

Scale Interval |

0.1g |

0.2g |

|||||||

|

Accuracy(??) |

±0.2g |

±0.5g |

|||||||

|

Detecting Speed(Max speed) |

155pcs/min |

140pcs/min |

|||||||

|

Maximum Belt Speed |

70m/min |

70m/min |

|||||||

|

The Weighed Product Size |

Width |

220mm |

290mm |

||||||

|

Length |

350mm |

400mm |

|||||||

|

Height |

70mm |

110mm |

140mm |

170mm |

|||||

|

Weigher Platform Size |

Width |

230mm |

230mm |

||||||

|

Length |

450mm |

||||||||

|

Height |

80mm |

120mm |

150mm |

180mm |

|||||

|

Sensitivity |

Fe |

?0.5mm |

?0.7mm |

?0.7mm |

?0.7mm |

||||

|

SUS |

?1.2mm |

?1.5mm |

?1.5mm |

?2.0mm |

|||||

|

Product Storage Quantity |

100 kinds |

100 kinds |

|||||||

|

Segments Number of Sorting |

2 or 3 |

2 or 3 |

|||||||

|

Rejecter |

Rejecter Optional |

Rejecter Optional |

|||||||

|

Power Supply |

AC220V (Optional) |

AC220V (Optional) |

|||||||

|

Degree of Protection |

IP30/IP54/IP66 |

IP30/IP54/IP66 |

|||||||

|

Body Material |

Stainless Steel (SUS304) |

Stainless Steel (SUS304) |

|||||||

Application

- Checking underweight / overweight products

- Identifying missing components in a package

- Feedback to the batching system

- Product sorting by weight